Case Study |

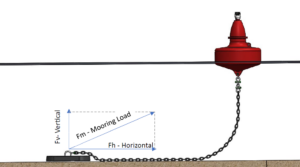

Clump weights are the simplest of omnidirectional and directional anchoring solutions. They are not efficient however offer some vertical capacity preventing uplift, therefore can be conveniently deployed to prevent both lateral and vertical loads combined. They can also be used to improve mooring systems by supplementing anchor catenary weights where additional clearances are required in the way of obstacles such as pipelines and cables. They can be used for the stabilisation of floating offshore wind turbines, wave energy converters (WEC), floating tidal stream devices and offshore aquaculture installations.

Sustainability

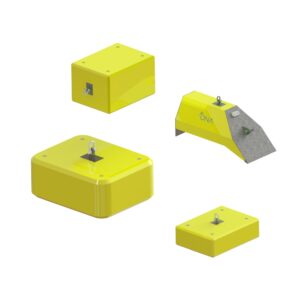

Clump weights can come in several forms and materials and should be chosen with due consideration to design load directionality, installation, corrosion resistance and impacts on benthic structures on the seabed. Deployment of clump weights where they will lift and continuously smash the seabed should be avoided. Similarly, the choice of anchoring connection and ground chain should avoid damage to the adjacent seabed.

Safety

ONA Marine offer concrete and steel clump weights for mooring uses. They are designed and built for the marine environment and come with safe lifting connections to ensure the clumps can be safely transported and deployed. Clump weights by their nature require to be safely lifted and deployed by marine type cranes with due consideration of their static and dynamic loads including necessary tagging considerations near the splash zone. Installation sequences are required to reflect the integrity of the mooring components and potential clump weight interaction during deployment.

Clump Weight Material

By far the most efficient material for clump weight efficiency is cast steel. Concrete anchors are physically larger for the same weight however can readily be moulded and customised. See the table below from a comparison of three basic materials in salt water. It can be seen that in salt water there is a reduced loss in efficiency in cast iron due to it’s high density.

| Factor | Cast Iron | Reinforced Concrete | Sand |

| Density in SW | 7.10-1.03=6.07 | 2.50-1.03=1.47 | 1.8-1.03=0.77 |

| Weight/m3 | 6.12 t | 1.47 t | 0.77t |

| Volume/10t | 1.6m3 | 6.9m3 | 13.0m3 |

Form of Clump Weight

The selection of form of a clump weight is also important to ensure consistent mooring outcomes. Pyramid or block sinkers can be used to either act vertically on a mooring line or alternatively anchor a mooring leg to the seabed. They are normally large and sixed to provide mostly vertical deadweight to the anchoring solutions. Deadweight anchors are typically placed where you would position a conventional anchor such that lateral (horizontal) loads are prevalent. They do offer some vertical capacity but are generally lower in profile to prevent toppling. In some cases, they can be shaped to partially dig into the seafloor (key) and provide additional lateral capacity.

Mooring Design

Mooring design and the selection of clump weight materials, size and form should always be undertaken using engineering judgment and acumen. As noted above several factors should be included in the selection process. The risk including consequences in a loss of position and failure should shape the criticality of each factor and associated mooring equipment considerations. ONA Marine are committed to assisting and informing your choices.